B. BASTITA

Free-Lance Researcher

98, rue Jean-Renaud Dandicolle - 33 000 BORDEAUX ñ FRANCE

Abstract

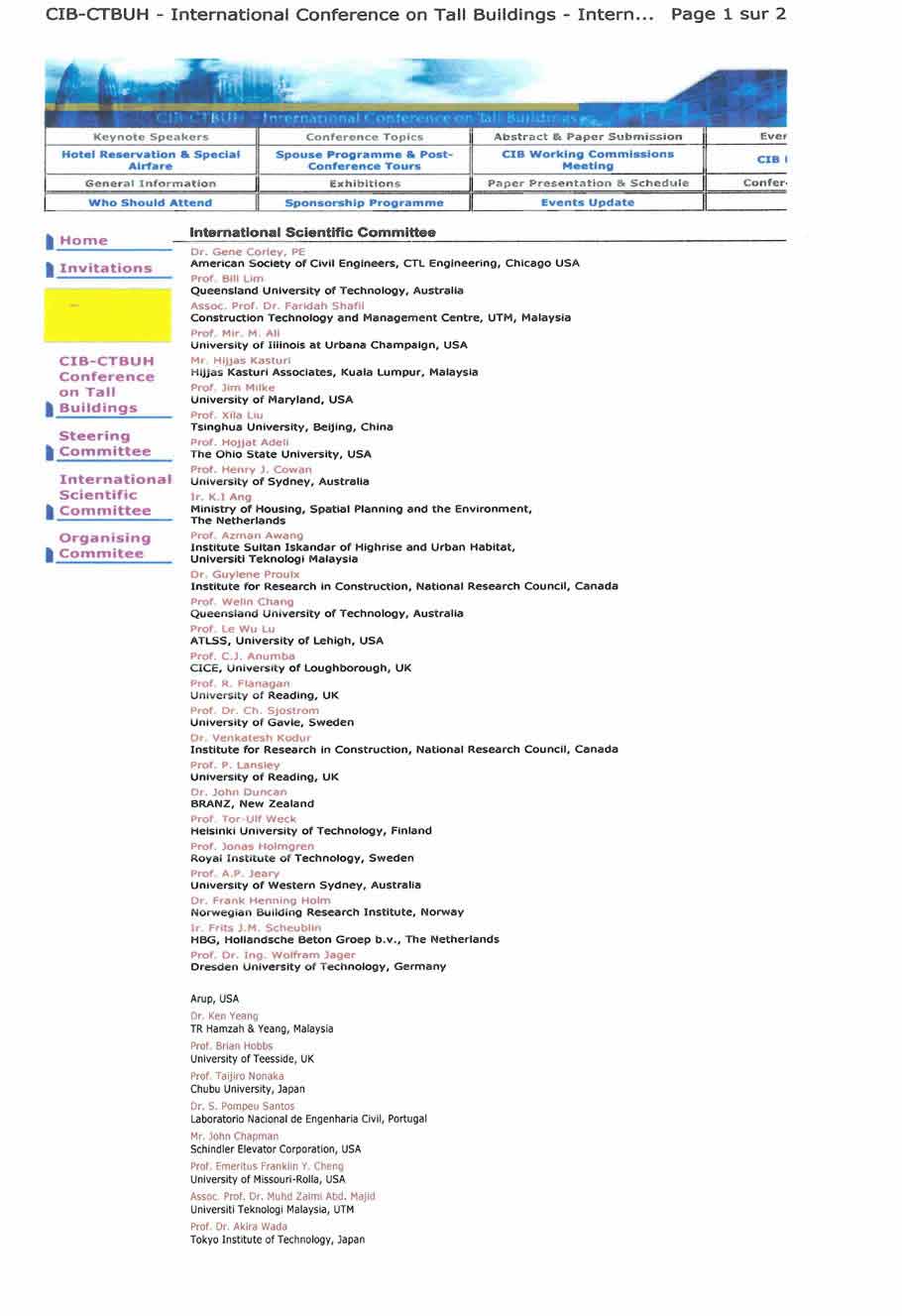

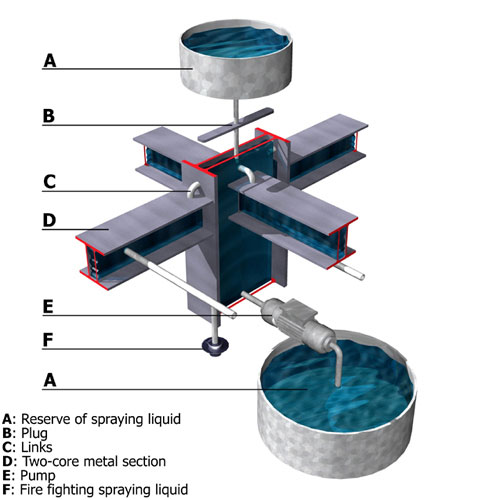

The concept is a combination of load-bearing metal frame and fire-fighting system.

The principle is based on the use of the metal frame as the spraying liquid supply to the sprinklers. In this way, the system ensures, at the same time during a blaze, the liquid supply of the fire-fighting system and the cooling of the frame that keeps its mechanical properties.

It is suitable on buildings built with two-core metal section as IPE, IPN, HPE and HPN or others. The metal section are upgraded by plugging and drills are positioned at the interconnection. The liquid supply is operated through the usual ground reserves and conveyed by means of pumps, or in case of very high buildings, by gravimetry using reserve on the roof. In order to follow the maintenance of the whole system, a draining device can be fitted on the base of the building.

Apart from technical and economical aspects, one of the most important improvements is the possibility for rescuers, in case of blaze, to intervene with more security and for a longer period.

Keywords: Tall buildings, Life-safety, Structural integrity, Security, Fire-fighting, Load-bearing metal frame.

September 11, 2001, has highlighted the weakness of load-bearing metal frames when subjected to very high temperatures.

According to the expert appraisal report drawn up by the American Society of Civil Engineers, two determining factors must be taken into consideration in the collapsing process of the Twin Towers:

. Heat: concentrated heat weakened the load-bearing metal frame; the continuous overheating of several spots of the frame led to different distorsions on the metal sections (expansion, contraction and endothermic reactions), and altered the mechanical properties of the load-bearing metal frame.

. Load factor and massive bulk: it has extensively contributed to the collapsing process. Despite having been hit second, Tower 2 fell down first. The impact was lower down than on Tower 1; therefore the load above the point of impact was much heavier; hence, the re-heating time needed to make the metal frame distort was much shorter.

Priority given to the following work is to ensure the resistance of buildings and allow rescue teams to reach the scene of an incident, without running into risks such as those brought to light by the World Trade Centre disaster.

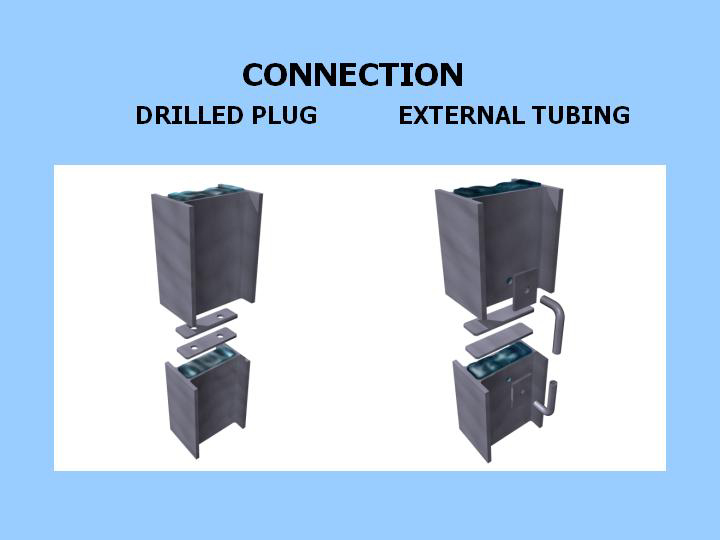

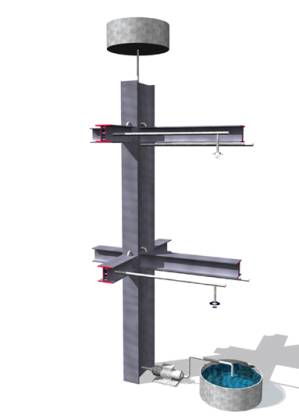

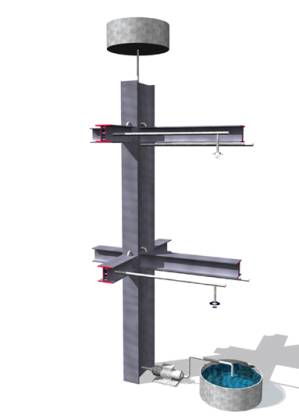

The process is very straightforward. It is based on the use of the load-bearing metal frame to convey the spraying liquid to the fire-fighting outlets. In this way, at the same time during a blaze -for instance-, the system ensures the liquid supply to the sprinklers and the cooling of the frame, that maintains its mechanical properties.

The system is compact and easy to implement. Its components exist already, or are easy to manufacture.

The whole system is less expensive than buildings equipped with standard fire-fighting systems. The removal of the main fittings supplying the sprinklers, as well as suppression of casing, leads to savings in materials and manpower, which can be used to finance the alterations brought about by the implementation of the new system.

In addition to increased safety, the process also leads to lighten and make more compact the construction, while saving space.

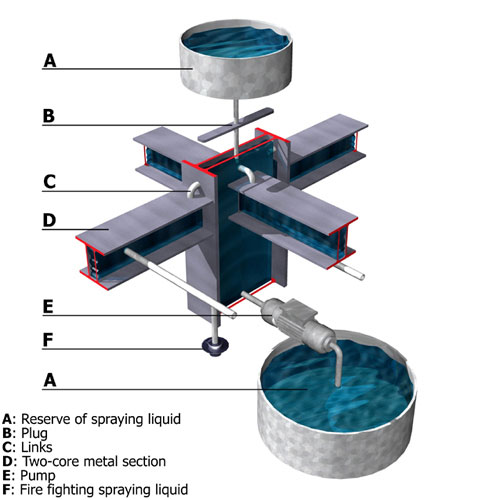

The process comprises three main components:

- The load-bearing metal frame

- The automatic fire-fighting system

- The storage of spraying liquid

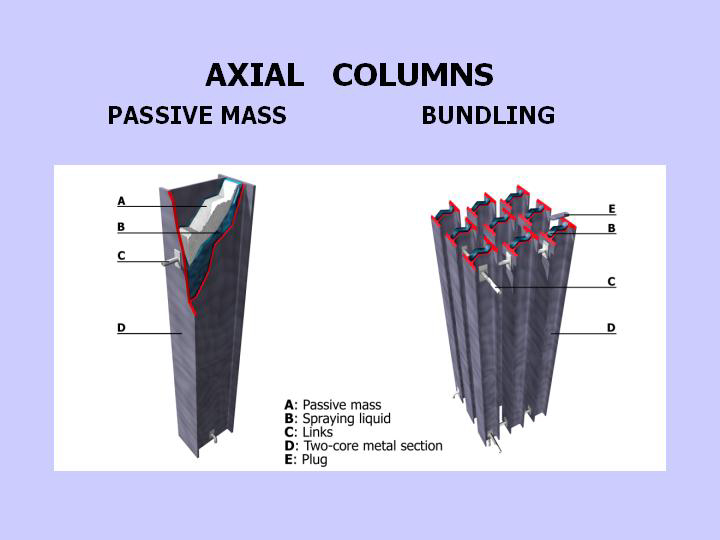

1. The load-bearing metal frame

Framework is made up of standard two-core metal sections, or metal sections specially designed for the implementation of the process. According to the type of construction, metal sections can be fitted together by simple arc or MIG welding.

Nevertheless slight alterations are necessary to ensure the flow of spraying fluid; the two-core metal sections need to be preplugged at their extremities and drilled when being interconnected.

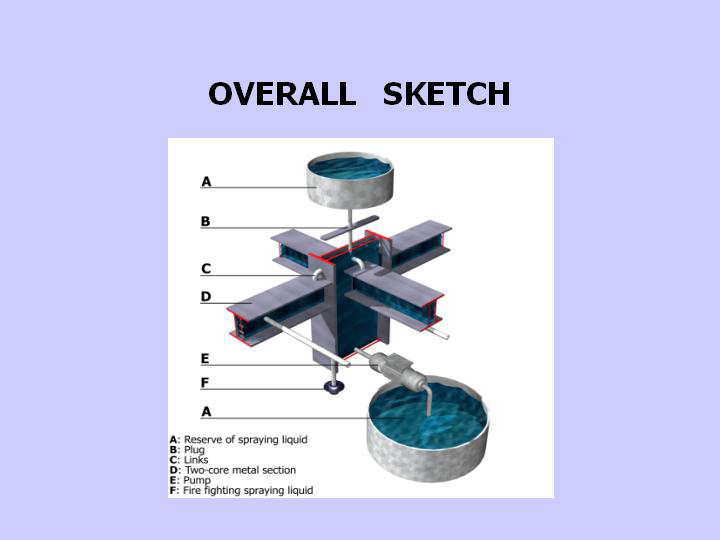

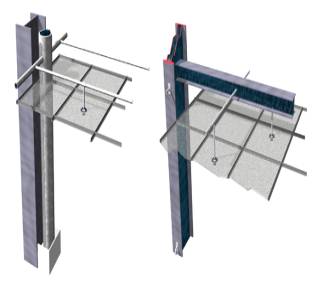

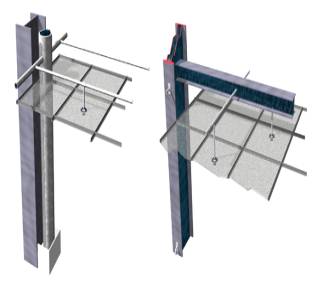

The connections can be achieved in two different ways:

- Either, a direct connection, drilled plugs welded end to end (it is also possible to use drilled plates). Plugs or plates must be, at least, as thick as metal sections, and made of the same material, so as to make the welding easier, on production lines or on building site, and avoid an inherent weakness.

- Or external connections through conduits, rigid or flexible,on core, flange or any other position on the metal sections. Such external connections can be welded or bolted.

Whichever way is used, platens need to be fitted to compensate for the weakness due to the drilling.

2. The automatic fire-fighting system:

The current automatic fire-fighting systems (sprinkler type) allow the implementation of the process; in fact, they will have to ensure the automation of the whole system. If a blaze occurs, the fire-fighting system starts running (thermosensible bulbs, bimetallic, or any other initiating system); spraying fluids on fires lead to set off the flow of cooling liquid within the framework, ensuring the cooling of the framework.

Should the blaze increase, it would lead to the start-up of additional sprinkling outlets; therefore, the liquid flow would increase, which would ensure a still effective cooling of the load-bearing metal frame.

There is no risk of metal section exploding. In the theoretical event that intense heat would lead sprinkling fluid to boiling point, the steam produced would be naturally evacuated through the active sprinkling outlets.

The fact that the sprinkling liquid could possibly, still in theory, reach high temperatures, does not alter its cooling function.

The sprinkling liquid could be water, with or without an additive, or a specific fluid according to the builder’s preference.

3. The storage of sprinkling liquid:

The storage of sprinkling liquid can be constructed in various ways. The most common, and frequently used, is the ground storage unit, from swimming pools supplying the whole fire-fighting network.

Alternatively, they can also be composed of roof reserves, using gravity fed; they can be specifically designed for this use; in the future, they could also be combined with other security fittings, such as anti-seismic counterweight, currently under experimentation.

The combination of the two above mentioned systems can be anticipated, in order to make the fluid supplying more secure and make easier the pressurisation of the load-bearing metal frame.

Now, we are going to take up some issues raised by the process.

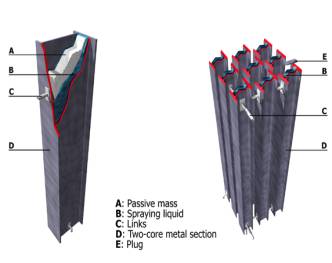

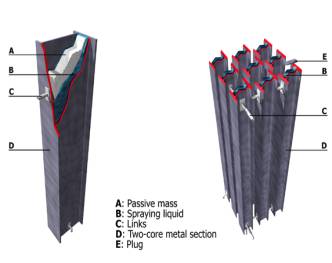

. Pressure of the water column

As we are talking about tall buildings, a problem arises, related to the pressure exerted by the liquid column on the internal bases of metal sections.

Faced with this issue, two solutions can be imagined:

- The use of large metal sections with an internal core; this passive mass would replace a large part of liquid, without preventing it from flowing; In this way, the pressure would be significantly reduced.

The passive mass could be of different materials, according to the builder's preference.

As regards to its installation, it is possible to fix it on a central axis, welded on the inner side of the plugs; it could also be ensured by the shape itself of the passive mass (grooved surface or chocking).

- The pressure exerted by the water column can also be decreased by aligning thinner metal sections together and connecting them so as to allow the flow of spraying liquid; as a result the inner surface has increased, which automatically reduces the pressure per cm2.

It is possible to combine these different systems (bundles, passive mass or simple metal section), depending on the characteristics of the construction. It is obvious that all these metal sections could be adapted in the plant or on site, regardless of their shape, since their adjustment would involve standard techniques.

As regards to their size, the sections can be mass-produced; they can also be modified on construction site, which could be easily achieved by professionals.

Corrosion risks are minor since the metal frame is permanently filled, like most of the current fire-fighting systems.

With the view of maintaining the system, simple draining plugs can be fitted at the base of each metal section or series of sections.

If we want to summarize the process, we can say:

Robustness and safety: this system can prevent buildings from collapsing, allowing rescue teams to intervene on the spot in greater security, and thus save lives.

Cost-effectiveness: substantial savings can be made on the current fire fighting installation (supplying pipes, manpower, materials and surface) allowing the implementation of this new system without any additional costs.

In conclusion, the implementation of this process is possible with current technologies.

The process integrates systems commonly used in current construction (such as fire-fighting systems); besides, saving the buildings avoid any additional setting up of new security systems (especially for emergency evacuation).

Therefore, it avoids redundancy of materials and subsidiary security systems.

With such an upstream approach of security buildings, the system allows us to protect the construction, and even more important to save the lives of the occupants -which is, at the end of the day, the ultimate goal. Buildings can be reconstructed, not the human lives.

Acknowledgements :

When writing this paper, the ad hoc structure comprises :

Bernard BASTITA, Inventor

Virginie BASTITA, Teacher

Jean-Pierre PETORIN, Engineering consultant

Bruno JACQ, Architect, Computer graphics designer

Didier QUEMENER, Consulting Architect

This project do not get any subsidy or development aid.